We collaborate closely in the development of medical and surgical devices. Our micromechanical and electro-erosion techniques are particularly applicable to the manufacture of equipment and vertebral and intra-vertebral implants. The latter are for medical treatments and diagnostics or surgical operations on patients in various areas of medicine.

The perfection of metal is at the heart of our approach to mechanical machining

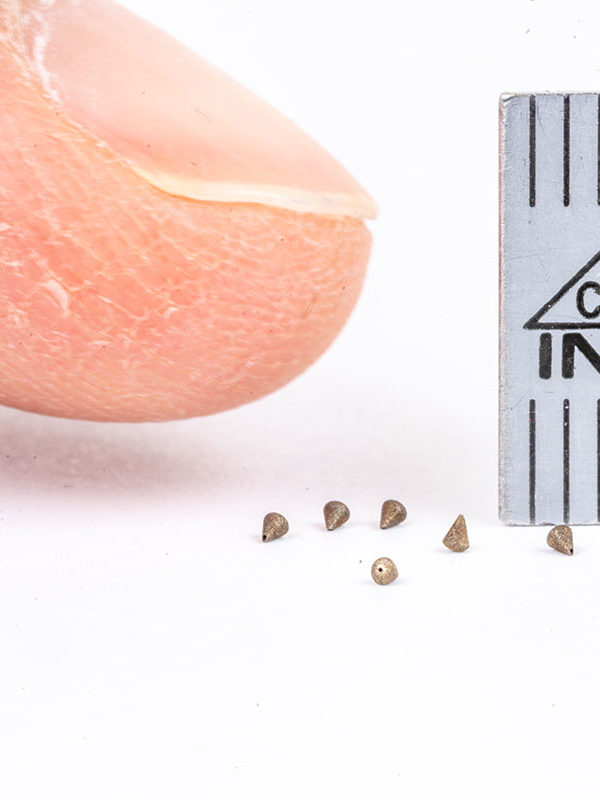

In this sector, precision is essential and we ensure a degree of precision of the order of microns in the machining of parts or metal components used for medical equipment, instruments and surgical ancillaries.

The micromechanics applied at Mecasoft are used to produce:

- mitral valves,

- vascular and cerebral stents,

- neural stimulators,

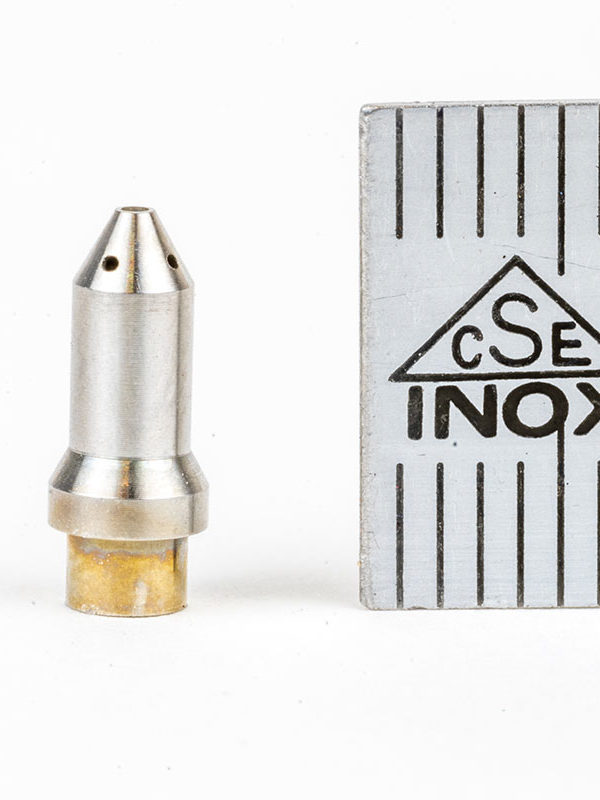

- ceramic and metal nozzles and precision inserts (micro-precision nozzles) for checking the flow of fluids,

- equipment for ophthalmological, endoscopic or dermatological operations,

- etc

Would you like to work with a single and reliable partner to design your high precision mechanical parts?

Perfect machining for individual implants or prostheses

We work in particular in stainless steel 316L and titanium, metals that are very well tolerated by the body and extensively used in the medical industry. Among other things, they are used in the manufacture of implantable products such as orthopaedic prostheses and intravertebral implants.

Erosion and micromechanics are particularly well suited to this domain in which the precision of each part is of paramount importance, in particular for high reliability equipment (medical devices) or individual implants unique to each patient. Our infrastructure enables us easily to carry out complete development from computer-aided design to quality control and certification of the equipment and finished size.

Mecasoft quality in the service of the health industry

Surgical precision gets its name from the strict requirements for all apparatus, instruments and tools used in this sector. They include parts that are sometimes particularly small and complex.

Machines using electro-erosion and micromechanics, in particular, are capable of producing this precision at such a level of complexity. This is especially the case for our 5-axis micro-milling machine or even our micro-cutting by wire centre, which is also 5-axis.

These two machining centres can be used to produce very elaborate parts, working in several dimensions in a single machining process. The surface finish obtained, which is crucial in this field, is also high, attaining an Ra of 0.05 µm.