Mecasoft are experts in the high precision cutting of metal parts by electro-erosion. Also known as EDM (Electrical Discharge Machining), or Spark Machining, this process results in machined components (metals, alloys, graphite, carbides, etc.) with a precision of the order of microns, whatever the hardness.

to precision

Our speciality: machining by electro-erosion

Electro-erosion uses an electric current to erode an electrically conducting material (steel, titanium, aluminium, stainless steel 316L, copper, Inconel, etc.) to give it the desired shape. The sparks produced by the current in a dielectric cause the removal of fine particles of material at the desired site, according to the program configured in the machine by the stations of the design office.

Precision cutting for all types of metals

For special applications such as sharp edges or corners, thin inserts, the electro-erosion technique used by Mecasoft is the most appropriate. Mastery of this technique enables us to offer you the production of products with complex shapes. Year after year, we widen the possibilities for the cutting of different metals, whatever the hardness or size, one-off or mass produced.

Our techniques also enables us to produce the desired surface finish, up to Ra of 0.05 µm. Surface finishes close to a polished mirror are possible produced with very low intensity currents.

The advantages of electro-erosion

- It enables small or large scale parts to be machined with remarkable precision for thicknesses of 1 mm to 400 mm or more.

- It enables complex shapes with spatial detail to be produced more accurately than with other machining techniques.

- It enables mass production of mechanical parts for sectors requiring a high degree of excellence (medical, aeronautics, aerospace, pharmaceutical, etc.).

- It enables working with all conducting metals, in particular those of the greatest hardness.

- It enables rapid prototypes to be produced for one-off products before starting industrial mass production.

Electro-erosion processes

Mecasoft has an extensive machine pool of renowned quality for cutting or drilling all your machined parts. Depending on the type of part to be machined and the result expected, we can offer you classical machining techniques or those requiring electro-erosion and, in particular, three electro-erosion processes: by wire, by sinking or by rapid drilling.

Depending on your requirements, we will recommend additional techniques, as appropriate, such as additive or laser manufacturing. Whatever your requirement, Mecasoft will accompany you from A to Z in its production.

01. Electro-erosion by wire

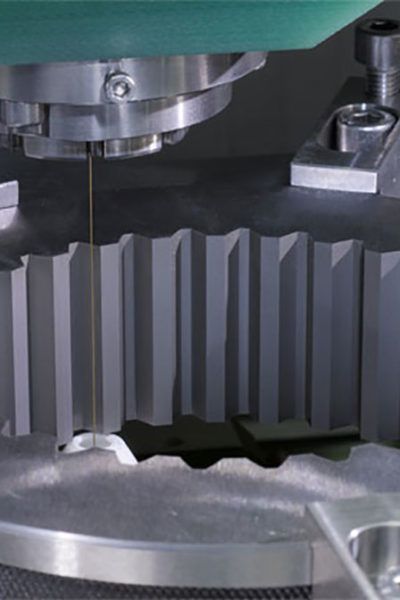

In the case of electro-erosion by wire the part to be cut is in constant contact with the dielectric (deionised water or oil). A metal wire conductor, driven with a continuous flat and angular motion, cuts the part according to the surface configured in the machine. Owing in particular to the very fine metal wire (from 0.02 mm), this process is particularly suited to machining corners and sharp edges or complex profiles.

Mecasoft has a wide pool of high performance machines for products from a few grams to 2 tonnes, of over one square meter in area. Among the usual shapes we can cut, among others, internal teeth, key slots, racks, cylindrical gears with straight, spiral or conical teeth.

02. Electro-erosion by sinking

An electrode tool with a shape complementary to the article to be machined, sinks into the material to give it the desired shape, with a gradual vertical motion. It is therefore possible to work particularly hard materials. This technique is particularly applicable to moulds, extrusion tools, dies, taps, etc.

Mecasoft has an extensive pool of machines that enables us to manufacture parts that can also be more than one square meter in area. Horizontal surfaces, like all upper surfaces, can thus be formed into the most complex 3D shapes. This technique is also used for holes with a vertical square, rectangular, hexagonal or even spiral cross section.

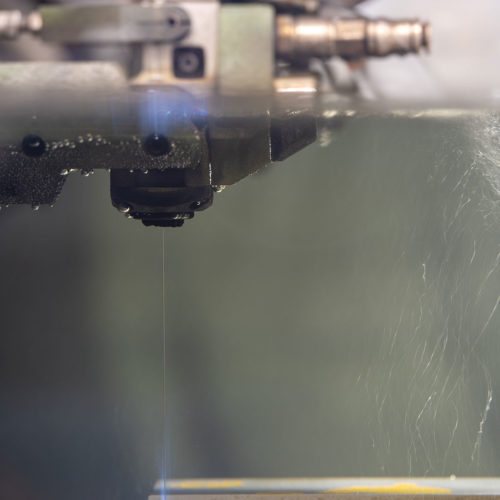

03. Electro-erosion by drilling

Resulting from the use of sinking techniques with a very narrow cylindrical electrode moving vertically, electro-erosion enables the rapid drilling of very hard materials. The electrodes can be tungsten, brass or copper, depending on the type of material to be drilled, the dielectric fluid circulating at its centre eliminating the metal particles removed.

Owing to its diversified set of machines, Mecasoft possesses the technology and expertise necessary to drill any metal material. They enable us to drill the material down to great depths, with a diameter from 0.2 to 3 mm (subject to a maximum depth/diameter ratio).

Applications go from drilling very small diameters for cooling turbine blades, the extraction of broken tools (taps or drills) passing through boreholes in non-destructive testing (NDT).

Electro-erosion: continuous improvement

Electro-erosion machines and processes have constantly evolved over time and today enable us to offer you results close to perfection. Thus, certain problems assumed to be associated with this technique have largely disappeared. This is the case, for example, of the “white layer” effect, a phenomenon that was due to heat and in the past caused an alteration in the surface of the object of a few atoms.