We accompany you at every stage of the design process of your machined parts, from the simplest to the most complex. With the aid of our design office, consisting of a team of engineers and specialists, Mecasoft places its expertise at your service for the assessment and completion of your project.

Our personalised advice for your machined parts

Our mission does not stop at the cutting out of your metal components. What guarantees that all our customers are satisfied is definitely the quality of the finished products and also our advice as experts in the field of mechanics to improve budgets, delivery dates and profits.

Drawing on many years’ experience, we assist you in choosing the most effective and competitive solutions at the design stage of your parts, the machining techniques to use and the most suitable materials for your requirements.

Accompaniment tailored according to the stage of your project

We advise and accompany you from prototyping to mass production. The methods implemented and the tooling required to machine your components effectively will vary depending on the maturity of your project.

From the production of prototypes for validation up to the preproduction or mass production phase (with extended breaks or continuously), we will help you to choose the most economical and efficient method.

Do you have any other questions concerning one of the stages of your project? Our company will make every effort to answer you!

Our design office handles your project with complete trust

- You will benefit from the knowledge of engineers and specialists in high precision mechanics.

- We will assist you in formulating your request, analyse your exact requirements and offer you the best solutions from the possible alternatives.

- We consider every stage in the development of your product, from assessment to completion, starting with prototyping.

- We will offer you a one-stop-shop, using an organised and effective process throughout our collaboration, including any subcontracting.

- We will guarantee you the precision and reliability of the final result obtained.

Our computer tools for the design of mechanical parts

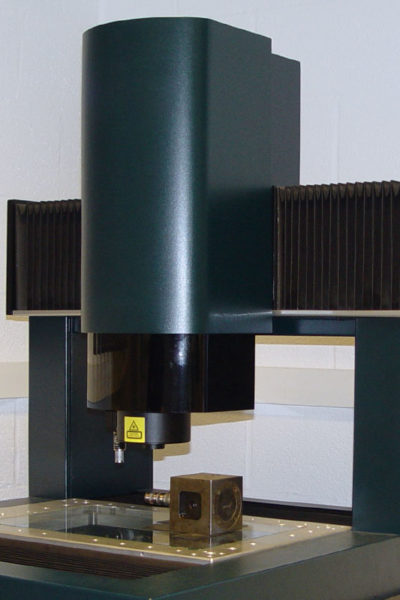

Computer-based solutions are the basis of the techniques used at Mecasoft. They enable us to analyse the feasibility of each project and provide a detailed plan from which we carry out accurate, efficient and automated machining, depending on the various techniques that we suggest.

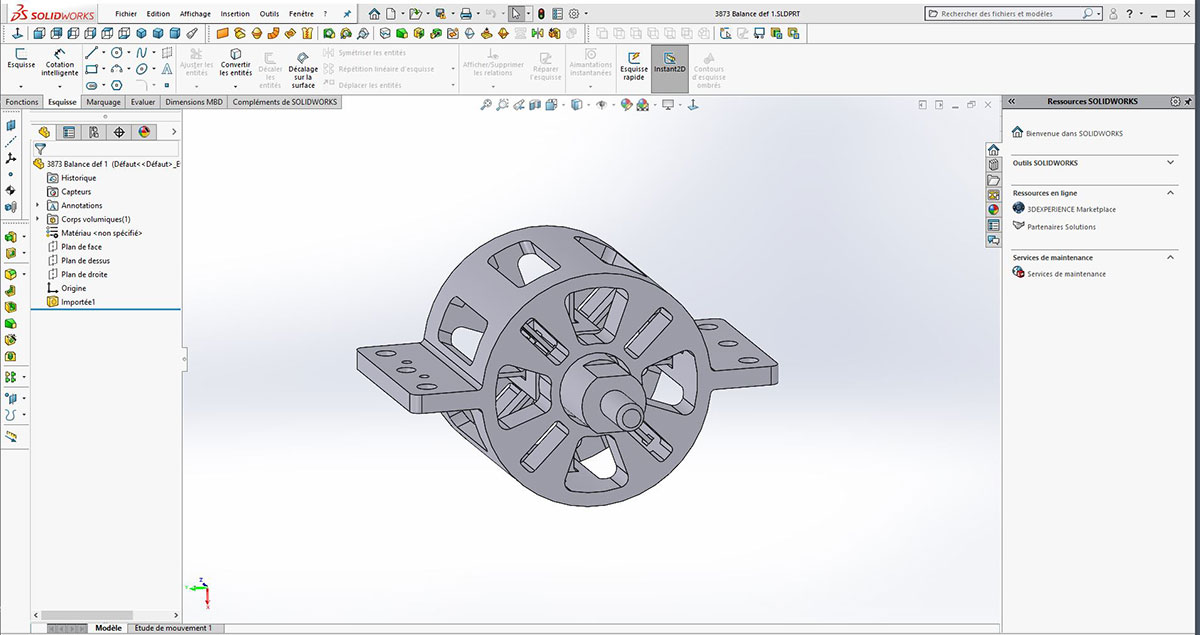

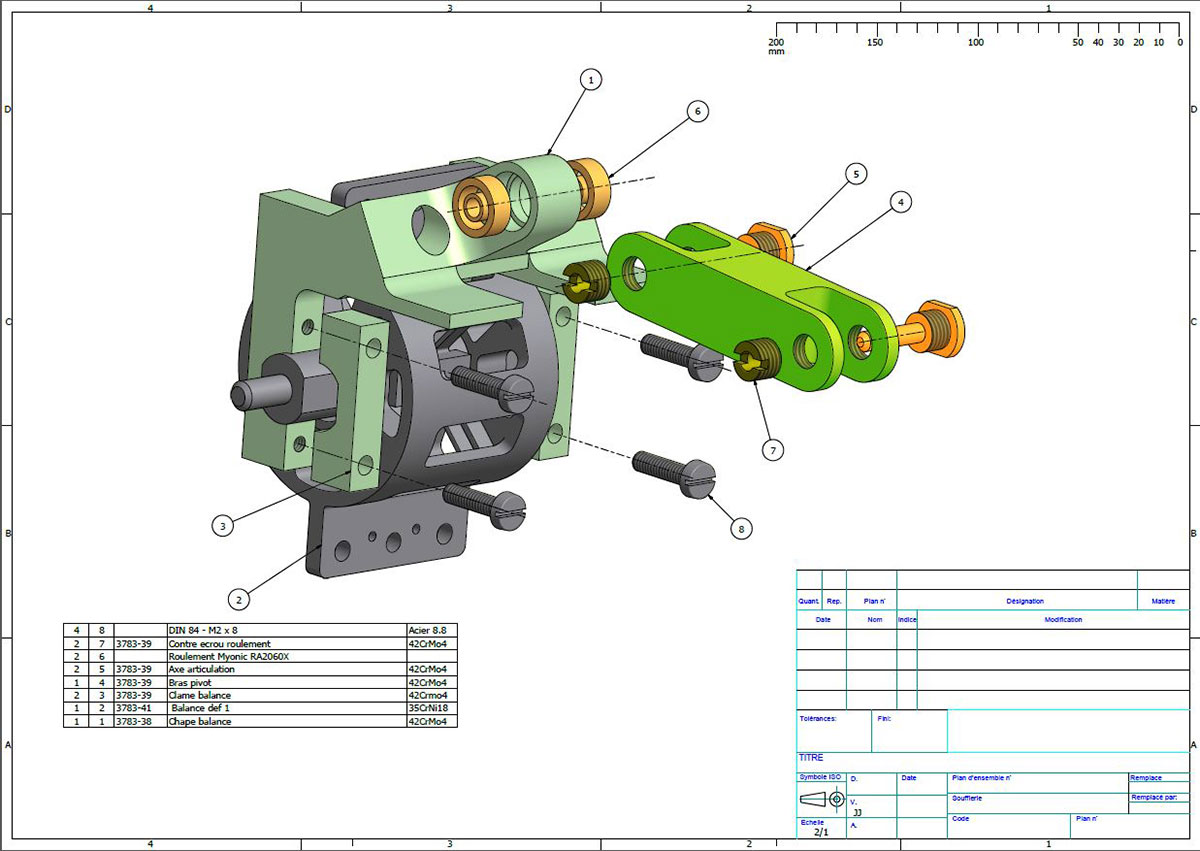

Computer Aided Design (CAD)

Using CAD, we integrate your drawings of the components to be machined, or produce them for you. Thus we obtain a complete 3D plan which enables us to observe the details and consider all possible problem areas. These can then be taken into account with a view to prototyping.

CAD is also crucial for mass production: it is at this stage that the components at the heart of the equipment are arranged and optimised. This reduces the quantity and number of operations necessary and therefore the machining time. In this way, we guarantee you the economic optimum.

Computer Aided Design and Manufacture (CADM)

The CADM computer utility links the work stations containing the profiles and contours of the product to be machined to the machine pool. It is therefore the control computer that controls and guides the machining of the part by the machine. This process enables us to obtain a finished result that is faithful to the established plan with a precision perfectly adapted to the defined requirement.

Mecasoft quality for each sector

Our engineers and experts benefit from long experience in the field of high precision mechanics. They have seasoned knowledge of the ideal materials and mastery of the techniques for cutting and drilling. Because of this, Mecasoft is an ideal partner for each sector requiring state-of-the-art machining for one-off or mass production parts.