Specialising in very high precision machining and noting trends in the miniaturisation industry, Mecasoft very soon decided to invest in various micromechanics techniques : micro-erosion, micro-cutting, micro-drilling and micro-milling. The performance of our 5-axis machines combined with the knowhow of our experts and our design office, enables us to respond to the most demanding requests concerning precision mechanics.

to precision

Unique precision for your machined parts

The various micromechanical processes (micro-erosion) used enable us to machine infinitesimally small parts. We are thus able to drill holes 20 µm (microns) in diameter, 3D details of only a few microns, as well as cut-outs with a precision also achieving microns.

Using these processes, Mecasoft is capable of tackling metals with the most varied properties, even those that are particularly hard, such as steel, titanium or carbide alloys.

Manufacturing all types of parts

The machines and techniques used by Mecasoft are especially suitable for machining mechanical parts that require a high degree of precision and detail. We can complete all your projects with mechanical parts, assembly parts and tooling parts whatever your sector of activity (aeronautical, aerospace, defence, medical, etc.).

Mecasoft is your one-stop-shop, efficient and guaranteed for the full completion of all your machining projects.

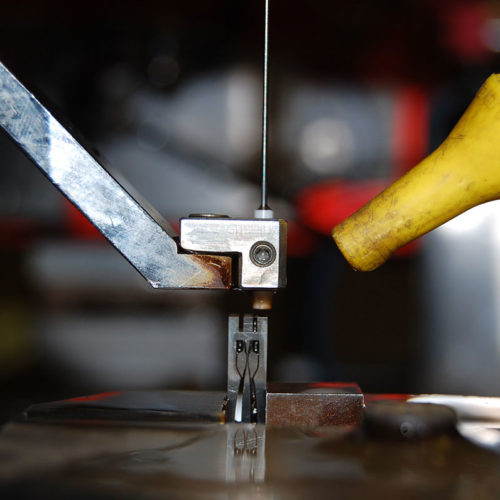

01. Micro-cuttinge

Micro-cutting can produce complex shapes and a level of detail in µm and in 5 axes in different metals. The surface finish of the final product is also exceptionally high.

Mecasoft is among the few companies to master the use of erosion wires with a diameter of down to 20 microns, that is four times thinner than a hair.

Degree of precision:

- Minimum roughness: Ra05 µm

- Minimum radius: 30 µm

- Minimum wire diameter: 20 µm

- Precision of machining: 1 µm

- Precision of positioning: 1 µm

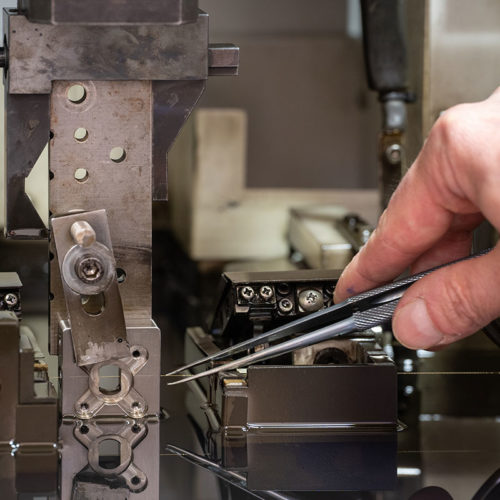

02. Microholes

This process consists in drilling or piercing small holes in any type of metal. The parts to be worked may be particularly delicate or the hardest. A common application is creating cooling holes in turbine blades.

Micro-drilling, used for producing microholes, uses tubular electrodes with a diameter down to 90 microns. Greater diameters are produced by planetary motion of the tool. Smaller diameters are produced by the size of the microelectrodes using a device with a very thin wire built into the micro-drilling machine. Experience and the precision of specific equipment enable us to drill holes of 15 µm.

Degree of precision:

- Minimum roughness: Ra 0.1 µm

- Minimum drilling diameter: 20 µm

- Precision of diameter: 5 µm

- Precision of centres: 2 µm

03. Micro-milling

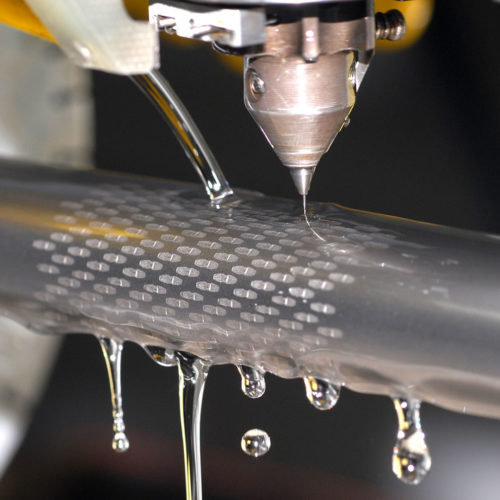

In this discipline, Mecasoft is a reference in Europe. Our company has mastered the technique of 3D micro-milling by electro-erosion. The precision obtained is of the order of the micron and the surface finish is excellent. This point is all the more important in surface texturing, producing motifs, reliefs, etc. using the 3D process.

Based on a 3D drawing, the CAM software generates a complex path which it sends to an electrode. The latter, such as a milling cutter, reproduces this path and thereby generates the motif on the surface of the part. The diameter of the electrode can be down to 30 microns and may be even smaller using a wire device built into a 5-axis micro-milling machine, for motifs of unrivalled detail and precision.

Degree of precision:

Minimum roughness: Ra 0.1 µm

Minimum drilling diameter: 20 µm

Minimum electrode diameter: 13 µm

Precision of diameter: 5 µm

Precision of centres: 2 µm