Critical components in a strategic and highly regulated environment

The defence industry imposes the highest standards in terms of reliability, precision, and traceability. The mechanical components used in military systems—whether optoelectronic modules, targeting devices, weapon subassemblies, or embedded systems—must operate under extreme conditions of temperature, vibration, shock, and electromagnetic environment.

Their performance is directly linked to the quality of their manufacture. Imperfect optical alignment, excessive play in an assembly, or poorly controlled tolerances can compromise the functioning of the entire system. Added to this is an absolute requirement for documentary traceability, with requirements derived from aeronautical standards such as EN9100, which govern production, control, and quality management processes throughout the defence supply chain.

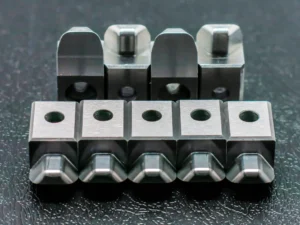

Parts for this sector are often made of very hard materials (nickel alloys, martensitic stainless steel, titanium, 13-8, 15-5, or 17-4 hardened steels), and their shapes are often very complex: internal housings, calibrated bores, deep grooves, invisible internal channels. Their traditional machining poses many challenges, particularly in terms of geometric stability and compliance with tight tolerances.

Electroerosion (EDM) and micromechanics as a response to military requirements

Electrical discharge machining, thanks to its lack of mechanical stress and its ability to machine complex internal geometries in highly resistant materials, is establishing itself as an essential technology for this sector. Wire EDM, for example, can be used to make precise, clean cuts with sharp angles, while ensuring a high and consistent surface quality. Die-sinking EDM is suitable for manufacturing cavities, technical housings, or details engraved into the material with extreme precision.

For certain applications, micro-drilling by EDM is essential: it allows calibrated holes with very small diameters (less than 0.2 mm) to be made without burrs, without the risk of tool deviation, and with great depth. These holes are used in detection, energy release, or fluid guidance devices in sensitive military equipment.

Offering similar precision to laser drilling but at very high heights, it also provides surface finishes (Ra) equivalent to cylindrical and flat grinding and technical polishing. With verification by 3D dimensional control machines, these techniques enable the delivery of mechanical parts that meet rigorous metrological requirements (tolerances < 5 µm). Compliance with the plan, repeatability of dimensions, and complete documentation are at the heart of the process.

Mecasoft: EN9100-certified partner for the manufacture of critical defence components

Mecasoft has been EN9100 certified for several years and applies a quality policy inspired by the highest aerospace and military standards. It is capable of producing complex technical parts, individually or in small batches, guaranteeing complete traceability at every stage: material procurement, machining, inspection, packaging, and delivery.

In a turbulent geopolitical environment, the Belgian company is positioning itself as a local player, ensuring reliable forecasting thanks to its large capacities and playing the double-sourcing game by making available a large EDM-specialized machines fleet (cutting, sinking and micro-drilling). It is equipped to machine parts of various geometries, in the most demanding materials, while maintaining extremely fine tolerances. Dimensional control is carried out in an air-conditioned room using optical or tactile (probes) three-dimensional measuring equipment (CMM).

Thanks to its experience with military specifications, Mecasoft regularly collaborates with local and international integrators and equipment manufacturers in the defence sector. It supports its customers from the prototyping phase onwards, ensuring precise technical exchanges, a detailed understanding of requirements, and production that complies with the most stringent regulatory and technical requirements.